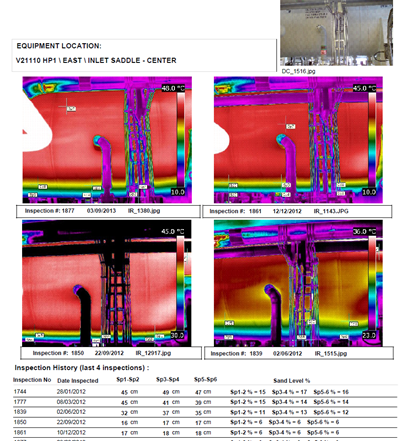

Pipe Integrity

Using basic thermographic principles it is possible for us to show areas of scale build – up, decreasing pipe wall thicknesses and weld discrepancies.

Benefits Of Thermal Imaging For Pipe Work In the Oil & Gas Industry

- Weld Integrity and qualitative assessment

- Detect metal fatigue and pipe wall thickness

- Identify scale buildup

- Corrosion detection

- Protecting Oil and Gas Infrastructure

- Understanding why pipes fail and blockages

- Data visualization

Thermographic Inspection Specification

- IR camera: Flir ThermaCAM P6402.

- Software: Reporter 8.0

- Thermographer: ITC Level II

- Extech Instruments for humidity/wind speed etc

- Leico laser distance measurements

Inspection Methods

- Initial visual inspection of the site order to familiarize with any irregularities or access problems.

- Images will then be captured comprehensively recording all data which may benefit from temperature analysis.