OptICAL GAS IMAGING FOR ANAEROBIC DIGESTERS?

We specialize in providing advanced Optical Gas Imaging (OGI) services for anaerobic digester plants across the UK. Our cutting-edge technology and expertise ensure that your operations remain safe, efficient and complient with UK Environment Agency guidelines.

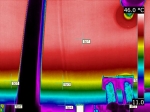

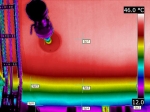

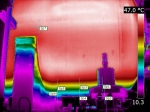

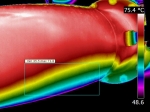

Effectiveness of Optical Gas Imaging

Optical Gas Imaging is powerful tool for detecting and quantifying gas leaks at anaerobic digester plants. Utilizing state-of-the-art equpiment such as the FLIR GFx320 and OPGAL EyeCGas we can identify even the smallest leaks that might otherwise go unnoticed. These cameras use infrared techonology to visualize gas emissions allowing for real-time detection and accurate quantification of leaks. This is crucial for maintaining the integrity of your plant and ensuring the safety of your operations.

Compliance with UK Guidelines

Our services are designed to help you comply with the stringent guidelines set by the UK Environment Agency. According to the SR2021 No 7 guidelines, it is essential to monitor and control gas emissions to prevent environmental harm and ensure operational safety. Our OGI services not only help you meet these requirements bu also provide detailed reports that can be used for regulatory submissions and internal audits.